MGfabrics

Technical Fabrics for Industrial Filtration

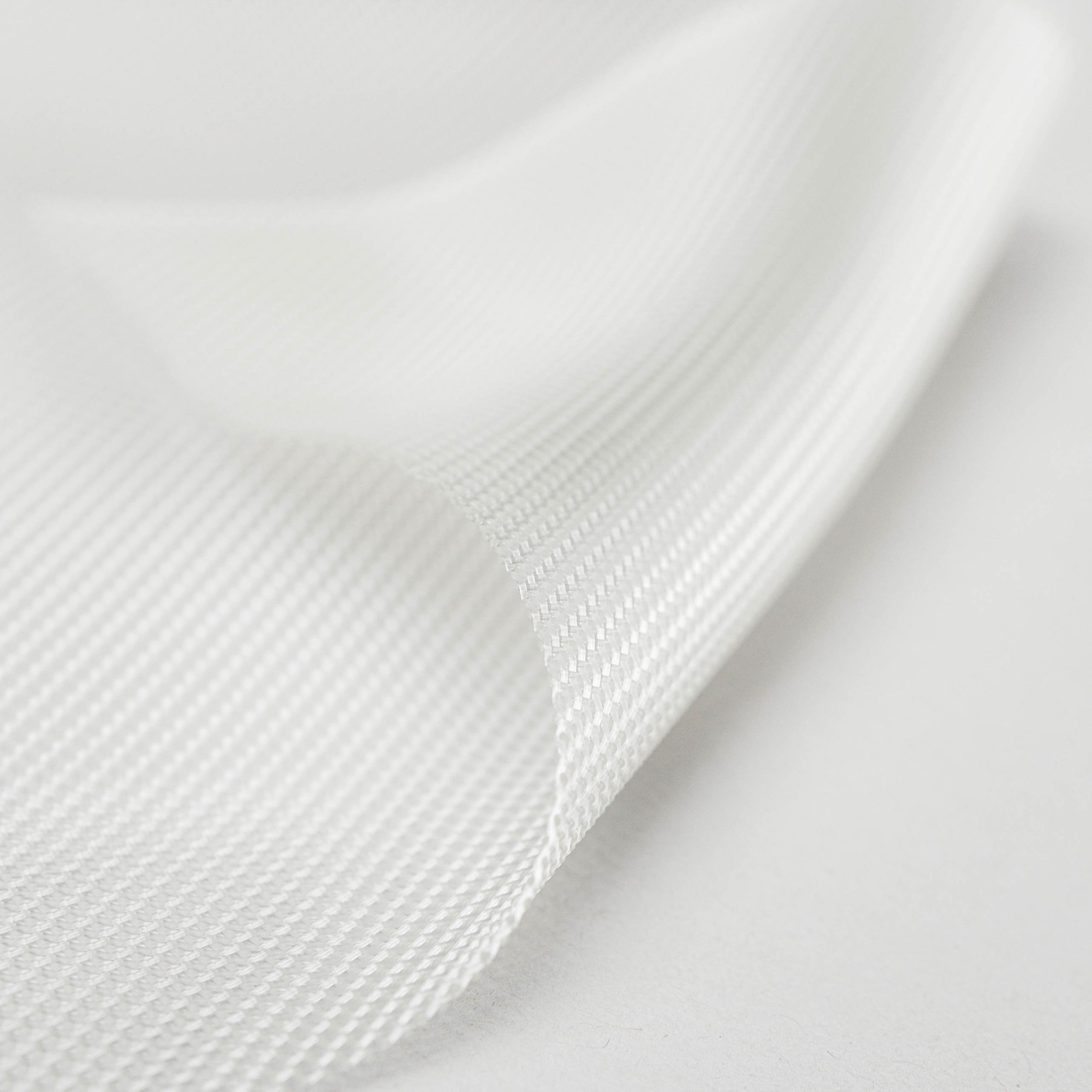

MGFILTRI is specialized in the production and distribution of technical fabrics made from polyamide and polyester, essential in the industrial filtration sector. These materials offer high performance and versatility across a wide range of applications.

Technical Description of Fabrics

- Filtration grade from 1 to 2000 microns.

- We can provide from roll to finished product in cooperation with certified plastic printers.

- Fabrics can have antistatic treatment or be FDA/EU certified for food contact.

- Upon customer request, we can also offer other fibers such as polypropylene, PTFE, etc.

Polyamide (Nylon)

- Strength and Durability: Excellent abrasion resistance, ideal for high-wear applications.

- Chemical and Thermal Resistance: Suitable for specific conditions, ensuring high performance.

- Porous Structure: Allows for good particle retention capacity.

- Flexibility: Suitable for various filter configurations.

Polyester

- Mechanical Resistance: Offers dimensional stability and resistance to chemical and biological agents.

- Stability in Humid Environments: Ensures efficiency in particle separation.

- Durability and Low Deformability: Maintains performance even under pressure.

Filtration of Liquids and Gases

Polyamide and polyester fabrics are widely used in the separation of suspended solids, liquids and gases, employed in bag filters, cartridge filters, and other filtration systems.

Food and Pharmaceutical Industry

Thanks to their compliance with health regulations, these fabrics are ideal for the filtration of food and pharmaceutical products, ensuring high hygiene standards and safety in the production process.

Water Treatment

Essential in the processes of industrial and municipal wastewater treatment, they contribute to the removal of suspended solids, oils, and other impurities in liquids.

Chemical Industry

The chemical resistance of polyamide and polyester fabrics makes them suitable for the filtration of solvents, oils, acids, and bases, used in refining processes and chemical production.

Advantages of Technical Fabrics

Polyamide and polyester technical fabrics are essential to the industrial filtration sector, offering high performance, durability, and reliability. They are also fundamental in the electronics and automotive sectors, ensuring efficient and safe filtration processes.

MGROLLS

Fabric Roll

Technical Fabric Roll Line

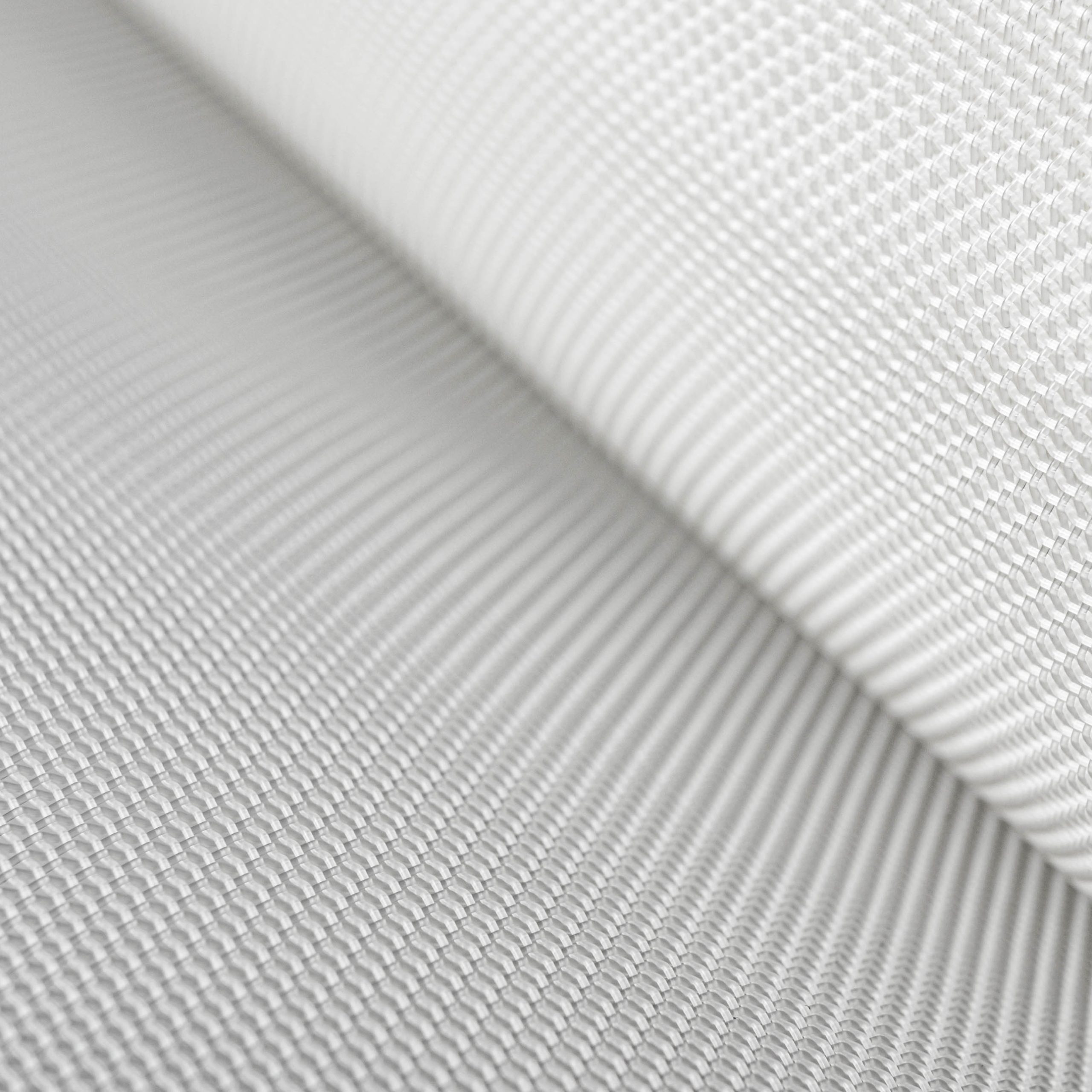

The MGROLLS line represents one of the product lines of MG Filtri, specialized in the production of technical fabrics in rolls for industrial filtration. These fabrics, available in various compositions such as polyamide and polyester, are versatile and adapt to a wide range of applications across various industrial sectors.

Advantages of MGROLLS

Fabrics One of the main advantages of MGROLLS fabrics is their high efficiency in particle removal. Designed to ensure superior performance, these materials perform well even in adverse environmental conditions. Additionally, MG Filtri offers the possibility to customize the rolls according to the specific needs of customers, minimizing material waste during processing.

Resource Optimization

Starting from the fabric roll, we are able to reduce the height to the required quota, thus optimizing resources and containing costs. MGROLLS can be produced using various cutting technologies, such as cold, thermal, or ultrasonic blades, to meet the specific needs of each customer. Our die- cutters are equipped with blades specifically designed for cutting fabrics, minimizing edge fraying.

Certifications and Safety

Furthermore, MGROLLS fabrics can be supplied in antistatic versions or certified for food contact, compliant with FDA and EU regulations. This feature is crucial for companies operating in the food sector, which need to ensure the maximum safety of their products.

Customer Service and Technical Support

Collaborating with MG Filtri means having access to dedicated customer service and qualified technical support. Our experienced team is ready to guide you in choosing the most suitable product for your needs, ensuring excellent results and guaranteed satisfaction.

MGBAGS

(Bags)

Filter Bags

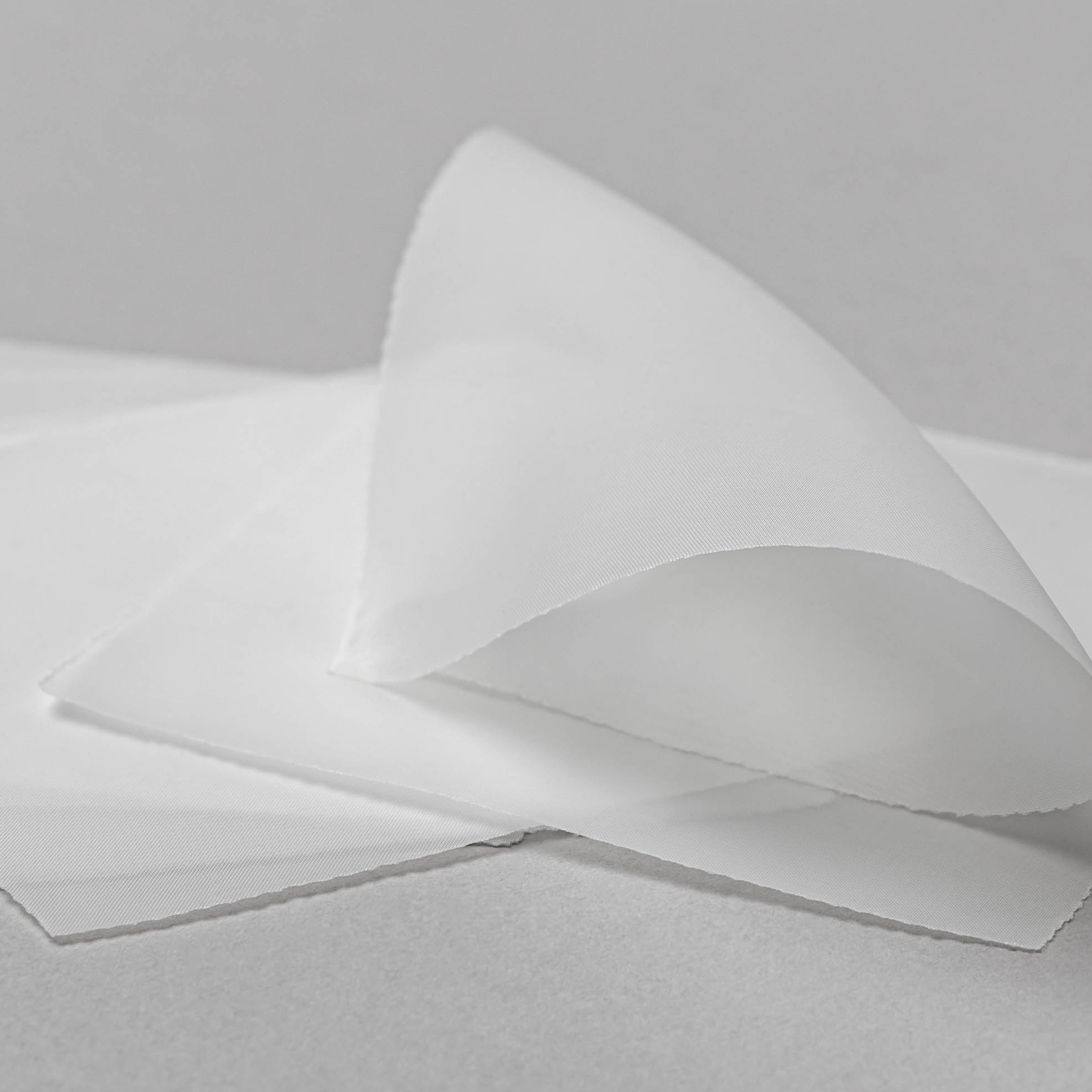

The filter bags from MG Filtri, made from various materials (Monofilament Nylon, Monofilament Polyester, Polyester Felt, Polypropylene Felt, PTFE, and Nomex), are essential components for industrial filtration. Thanks to their high-quality synthetic materials, these bags offer excellent resistance to chemicals and high temperatures, making them ideal for a wide range of applications.

Field of Use

Filter bags are widely used in critical sectors such as the chemical, pharmaceutical, and food industries, as well as in water treatment processes. Their ability to retain particles of various sizes makes them perfect for filtering suspended solids, powders, and other contaminants, thereby ensuring the quality of the final product.

Mode of Use

Filter bags are installed in filtration systems, such as tanks or production plants, where the fluid passes through the bag, retaining impurities. Due to their robust structure, these bags ensure a constant flow and long service life, significantly contributing to the efficiency of the production process.

Advantages of Filter Bags

Choosing filter bags made from polyamide and polyester offers numerous advantages, including:

- Resistance: Excellent ability to withstand chemicals and high temperatures.

- Durability: Designed for long-lasting performance, reducing replacement costs.

- Ease of substitution: Simple to install and remove, improving operational efficiency.

Additionally, filter bags are available in various sizes and shapes, ensuring adequate adaptability to any filtration system.

Types of Bags and Technical Data

- Ringed Filter Bags: Available in plastic or metal versions.

- Non-Ringed Bags: For direct mounting on pipes, with or without a drawstring for attachment.

- Custom Bags: Made according to required shapes and sizes, starting from fabric rolls.

- Antistatic Bags: Designed for specific applications requiring antistatic features.

- FDA/EU Certified Bags: Ideal for food contact, ensuring maximum safety for food products.

In summary, MG Filtri’s polyamide and polyester filter bags represent an effective and versatile solution for ensuring the quality and purity of products across various industrial sectors. Contact us for more information about our filter bags and see how we can optimize your filtration

processes!

MGTUBES

(Tubular)

Tubular Fabrics

The MGTUBES line stands out for the production of innovative and high-quality tubular fabrics, designed to meet the needs of various industrial sectors.

What We Offer

Our line includes:

- Tubular fabrics and filter socks or sleeves, available in single stitching, double stitching, or ultrasonic welding.

- Rolls of tubular fabric with customizable lengths, or cut pieces according to customer specifications.

- Tubular fabrics made from antistatic materials or certified for food contact according to FDA/EU regulations.

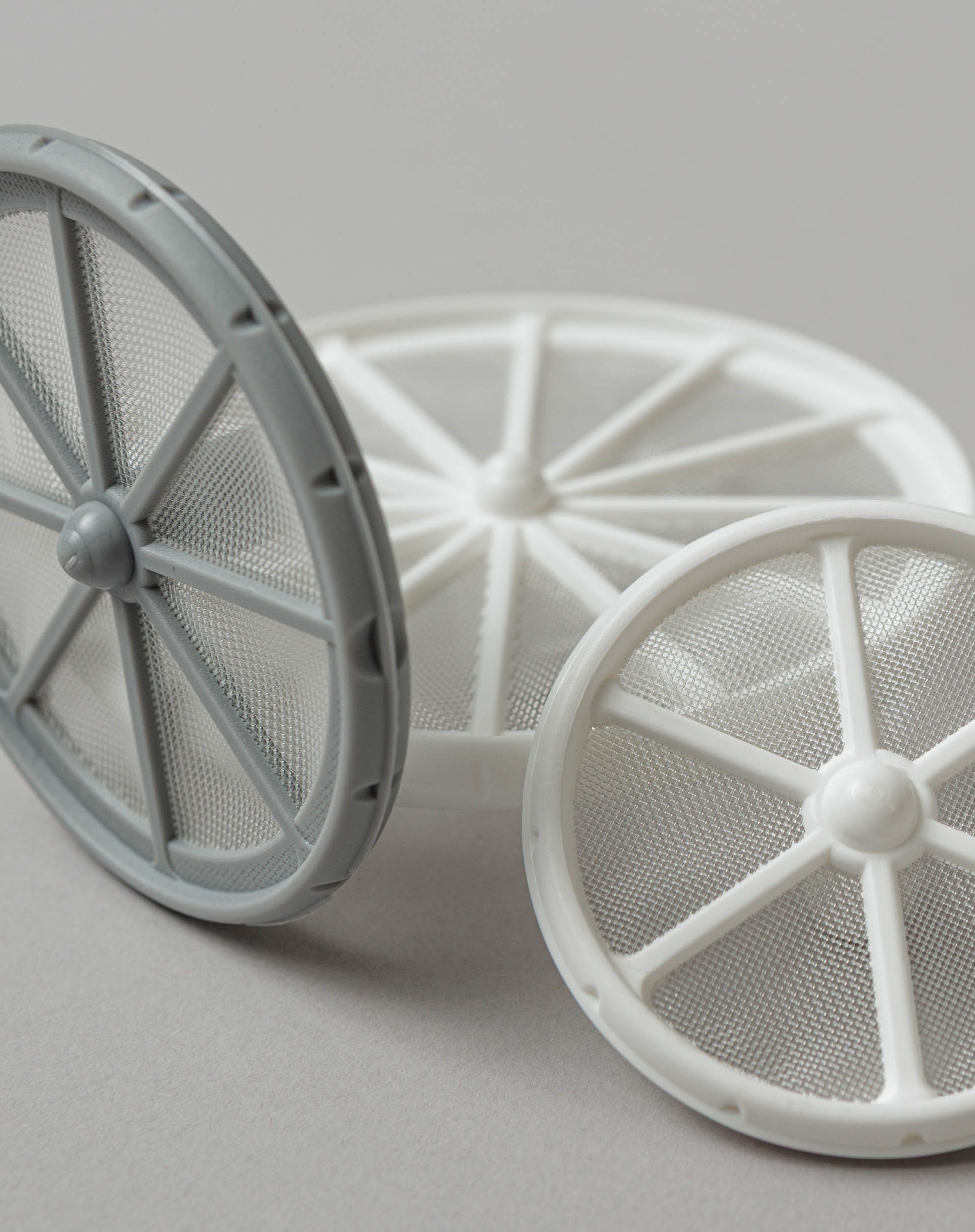

- Filters produced in collaboration with certified plastic printers.

Tubular Fabrics in Polyamide and Polyester

Features

The tubular fabrics in polyamide and polyester are synthetic materials crafted into a tubular shape, offering:

- Excellent mechanical and chemical features, making them ideal for a wide range of industrial applications.

Main Uses

MGTUBES tubular fabrics are mainly used in:

- Filtration: Employed in the production of cylinders for filter cartridges.

- Plastic molding: Suitable for various sectors, including automotive and household appliances.

Functions and Advantages of Tubular Fabrics

What They Are Used For

Tubular fabrics are designed for:

- Filtration: Ideal for retaining solids and impurities, ensuring pure fluids.

- Stability: Resistant to a wide range of chemicals, increasing product longevity.

- Versatility: Adaptable to different shapes and sizes, perfect for various plants and systems.

Advantages

The main advantages of our tubular fabrics include:

- Lightweight and easy to process.

- Excellent abrasion and deformation resistance.

- A wide range of applications, from industrial filtration to technical clothing.

In summary, the tubular fabrics in polyamide and polyester from the MGTUBES line represent a versatile and durable solution, essential for ensuring efficiency and quality across multiple sectors. Choose MGTUBES for innovative and high-quality products.

MGSHAPES

(Die-Cut Fabrics)

Die-Cut Technical Fabrics for Filtration

Die-cut technical fabrics made of nylon and polyester are fundamental components used in industrial filtration systems. These materials are specifically designed to ensure high performance in the removal of particles and contaminants from fluids and gases.

What is it

Die-cuts are pieces of technical fabric that are cut (die-cut) into specific shapes and sizes to fit particular applications. Made from nylon or polyester, these fabrics offer a combination of mechanical strength, dimensional stability, and filtration capacity.

How They Are made

The production of die-cut technical fabrics occurs through a precise cutting process. Here are the main steps:

- Material Selection: The type of fabric (nylon or polyester) is chosen based on the specific needs of the customer.

- Die-Cutting: Using cold, thermal, or ultrasonic dies, the fabric is cut into the required shapes.

- Quality Control: Each piece is inspected to ensure it meets technical and quality specifications.

- Customization: Die-cuts can be further treated for specific characteristics, such as chemical resistance or antistatic features.

What They Are Used For

Die-cut technical fabrics are primarily used for:

- Filtration of Liquids and Gases: They remove solid particles, dust, and contaminants from fluids and gases.

- Industrial Applications: They are essential in various sectors, including the chemical, pharmaceutical, and food industries.

- Dust Collection Systems: Used in suction systems to ensure a clean working environment.

Where They Are Installed

Die-cut technical fabrics are installed in various systems, including:

- Filters: Installed in tanks or filtration systems, where the fluid passes through the die-cut, retaining impurities.

- Ventilation Systems: Used to filter air in industrial and commercial facilities.

- Self-Cleaning Filters: Integrated into systems that require continuous and automatic filtration.

In summary, die-cut technical fabrics made of nylon and polyester are versatile and essential elements that ensure quality and purity in industrial filtration processes.

MGSPECIAL

With our fabrics we can create the filter system that best suits your needs. Baskets, hoses, nets, etc.

MG Filters: Tailored Solutions for Every Industry

- Understanding Needs: Every industry has unique requirements. MG Filters offers special customized products to meet the specific needs of our clients.

- Experience and Reliability: With years of experience in the filtration sector, we develop tailored solutions that ensure high performance and reliability.

- Technical Filters: Manufactured according to customer specifications.

- Technical Fabrics: Available in various sizes and materials.

- Special Treatments: Options such as anti-static treatments and FDA/EU certification for food contact, ensuring safety and compliance.

Various Applications:

- Filters for industrial applications

- Fabrics for air purification

- Solutions for liquid filtration